Continuous Improvement Displays: We Can Do That

At Big Visual, inspiration often comes in the form of unorthodox requests from our clients. Recently, one of the most rewarding, but labor-intensive, projects we’ve undertaken came from a new client.

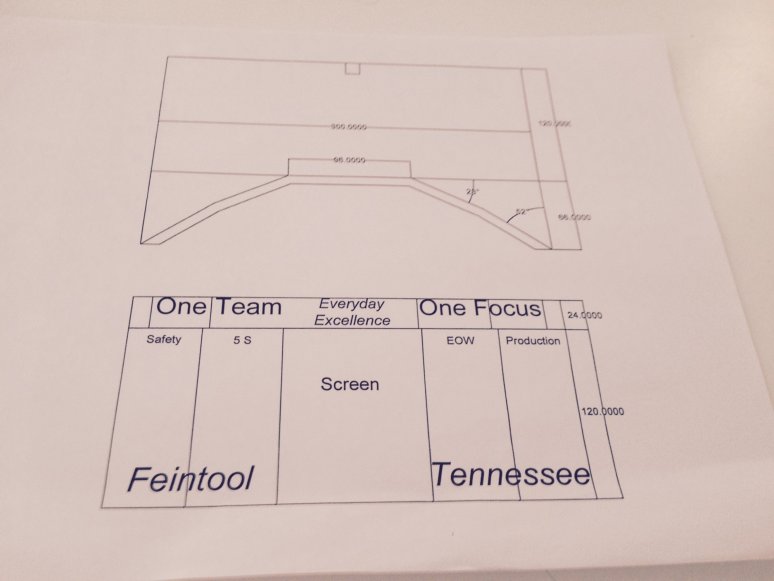

A representative from Feintool walked through the front door and asked if Big Visual could fashion a continuous improvement wall in their warehouse. They only provided simple renderings of a structure printed on two pieces of paper as a reference, so it was up to Big Visual to fill in the blanks, and we never shy away from a challenge. After some internal deliberations to decide how it could be done in-house (if at all), the Big Visual team went for it. It took many hours of hard work and creative problem solving, but the continuous improvement wall was successfully installed at Feintool’s Nashville.

You have to start somewhere: the original rendering given to Brand Imaging

What exactly is a Continuous Improvement Display?

You’ll find these types of displays in all kinds of workplaces, both corporate and industrial. They’re often displayed on walls and in break rooms and serve many purposes, such as tracking progress of projects, listing safety information or number of days without accidents, detailing processes and procedures, and reminding employees of company policies. Typically, this type of information is smudged on a dry-erase board or cluttered amongsheets of paper, but Feintool and Big Visual had a much grander vision: a striking multi-paneled display that commands attention.

Finished Continuous Improvement Display

Some Specs on the Finished Project:

Showcasing Big Visual’ s varied talents, this custom-designed display combines printed graphics and lettering from our print production team with the routing and fabrication of aluminum panels and lettering from the dimensional graphics team.

- Each panel is 120″ x 60″ (90″ wide for the center panel), held in place by a display structure. Many of the graphics and lettering (SAFETY, 5S, CI, KPI) are printed directly onto the aluminum panels with Big Visual’s flatbed printer.

- The lettering at the top of the panels (ONE, TEAM, ONE, FOCUS) as well as FEINTOOL and TENNESSEE, are 1/4″ acrylic dimensional letters routed with a brushed aluminum face.

- Each panel contains unique printed pieces, many of which are interchangeable and customizable. The safety “cross” graphic was originally a dry-erase laminate with adhesive backing, but now it incorporates printed small magnets to track accidents. The TEAM panel incorporates a vinyl printed map of the facility. Other printed elements have a velcro backing — like the plastic document holders on the CI panel. The TV mount was installed by the client, but it’s another solid example of how many creative things one can do with a large, multi-paneled structure like this.

When the idea was pitched, Big Visual just wasn’t sure how this might turn out. But it’s safe to say that this particular installation was a smashing success and really pushed the entire team to think outside the box and rise to the challenge. Big Visual plans to use this model and process to build similar workplace structures in the future. In fact, Feintool has already commissioned a few smaller versions of this same piece for their Ohio locations. If you want to make a big visual statement in your place of business, we’ re the company to do it!

You may also be interested in:

Nashville’s One-Stop Print and Sign Shop

3 Reasons to Shift All Your Print & Signage Needs to Big Visual: Over the past 30 years, Big Visual Group has had the opportunity to partner with countless business owners across Nashville. From entrepreneurs hustling to make their dreams come true, to large scale…

Our Flatbed Printers are Making Headlines

Digital Output took notice of Big Visual Group’s flatbed printing capabilities in their November 2020 issue. We were honored to be featured as the cover story. We regularly update our flatbed equipment and try new technologies to increase our production capacity...

A Titans Season to Remember: Adapting to Change & Expecting the Unexpected

Big Visual Group has partnered with the Tennessee Titans to provide them the best sign and print products since 2010. We have tackled interesting projects with the team, such as the Nissan Stadium rebranding in 2015, but 2020 might be our most unique season with them...