Guide to Photopolymer ADA Signs

Our vast sign shop in Nashville is filled with all kinds of impressive printing and sign-finishing equipment, constantly whirring, buzzing, and humming. Though it’s not the most physically imposing machine of the bunch, one of the most well-established and technologically advanced printers at Big Visual Group is the Nova Photopolymer Processor, used to print sleek, sturdy photopolymer building signs.

If you’re unfamiliar, photopolymer signs are often used to create ADA signs that are the wayfinding signs inside buildings and indicate bathrooms, elevators, room numbers, permanent spaces and more. They include braille to meet ADA compliance. Big Visual Group offers full photopolymer signage packages to ensure that your business or building is ADA compliant.

On to the machinery! Photopolymer signs are created by transposing a digital image to a film negative, putting it on a photopolymer sheet, exposing it to ultraviolet light, washing it, drying it, and exposing it again. Easy enough, right? No? Let’s break it down a little further.

Photopolymer Sign Materials

Photopolymer is a synthetic compound that hardens when exposed to UV light. Big Visual uses 19″ x 24″ sheets with an acrylic base, of various thicknesses, that’s topped by the 1/32-inch photopolymer sheet.

Photopolymer Sign Process

First, the sign is designed to fit specifications (approved by the client) on a computer. The image is mirrored (so it appears to be backward), and lettering must be in black (color is not added to the sign until the very end) on the clear film. A number of different photopolymer signs fit on the same sheet and go through the process simultaneously. (Printing one sign at a time would be costly and tedious).

In a process that is not unlike Tetris, multiple signs must be moved around in the prepress phase to fit onto the single sheet of film. Once all the images of signs are aligned, they are printed on the film.

The black and clear film negative is then placed atop the photopolymer sheet, and it’s ready to be exposed in the Nova Photopolymer Processor. After it’s vacuum-sealed (you don’t want any air between the negative and the sheet), it’s exposed to ultraviolet light for 5 minutes. Light passes through everything but the black lettering (which blocks the light), hardening the clear parts of the film.

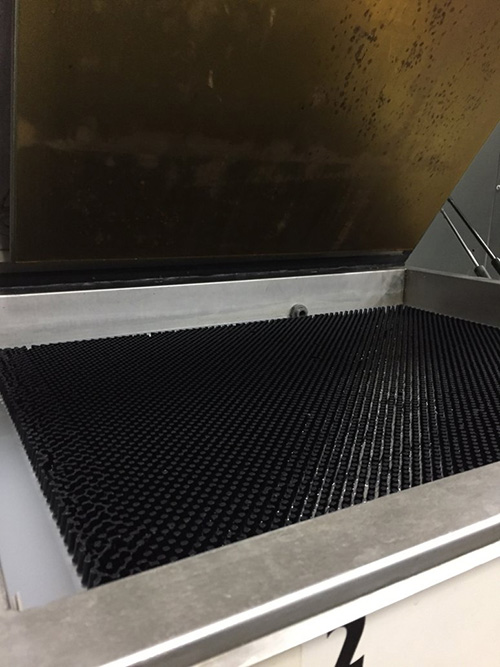

After it’s been exposed, it goes into a wash tank where oscillating bristles rinse it with tap water, dissolving the emulsion and leaving behind everything that was hardened by the light: your raised text and braille. The sheet then goes into a drying drawer on the machine for 15-20 minutes. For one final curing, the sheet undergoes the UV exposure process one more time, hardening the clear parts of the photopolymer.

The black and clear sheet with the transferred image then dries for 24 hours before it is sent away for routing: cutting out the individual signs from the sheets. Last, the signs are sent to the paint department, where, yes, they will receive a little color via a spray and wipe method, so that the lettering and background of the signs are different colors.

A completed photopolymer ADA sign (go Preds!)

Advantages of Photopolymer Printed Signs

One obvious advantage of photopolymer ADA signs is that they look clean, vivid and sleek. Aside from aesthetics, this process is desirable because it’s quicker and more cost-efficient than routing and engraving methods to create braille signs. Big Visual Group can turn around an ADA-compliant building sign project in 10 days with this technology.

Another distinct advantage to printing with photopolymer sheets is that the letters and braille cannot be removed from signs. It’s an unfortunate part of human nature, but people pick letters off signs all the time, whether out of boredom or for various mischievous reasons. With photopolymer signs, letters and dots are not attached with adhesive and cannot be removed, thus remaining ADA compliant.

We hope this gives you some insight into how we produce photopolymer at Big Visual Group. If you need to refresh your ADA and wayfinding signs and are interested in using photopolymer, holler at us for assistance.

You may also be interested in:

HOW TO TRANSFORM YOUR RETAIL SPACE FOR GEN Z

Generation Z, or simply “Gen Z”, is fascinating. They are a hybrid generation with their phones in hand and their eyes on the horizon. They’re a generation fully immersed in the digital world that wants to make a lasting impact on the physical world. Many…

Everything to Know about the SERVPRO 2024 Trade Show

Make a Great First Impression: We all know by now that first impressions are everything. As the trade show season approaches, it is more important than ever to have an excellently curated display that engages with prospective customers and addresses their needs and…

Nashville’s One-Stop Print and Sign Shop

3 Reasons to Shift All Your Print & Signage Needs to Big Visual: Over the past 30 years, Big Visual Group has had the opportunity to partner with countless business owners across Nashville. From entrepreneurs hustling to make their dreams come true, to large scale…